Get your EPR Registration and Compliance

for plastic waste

EPR

400+

Brands Associated

30+

Disposal Centers PAN India

10,000+

Rag-pickers empowered

100+

IEC Activities Done

What is EPR Registration?

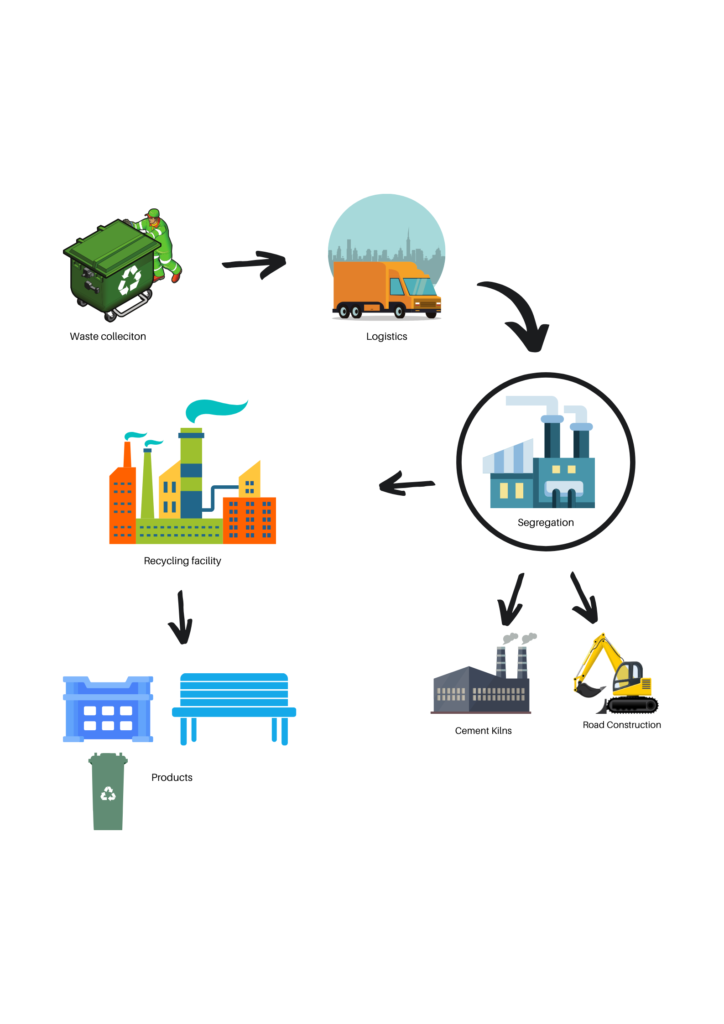

EPR registration for plastic waste is the responsibility of the management of disposal of those products once labeled as no longer useful by the consumers. Our main objective is to develop an easy and effective system that takes care of collection, segregation, and transportation of the material to the waste disposal facility which is approved by MPCB and CPCB as a professional agencies.

These materials are also used in Cement Kilns, pyrolysis, road construction, and recycling center on the basis of their quality.

CPCB EPR Registration Process

- The process starts with CPCB /SPCB

- The authorized waste management agency collects the agreed volume of post-customer plastic waste

- The waste collection agency will present relevant documents for proof of waste collection activity

- On behalf of PIBOM’s agency will submit a quarterly report to CPCB.

- After completion of the activity final report will be submitted by the agency to PIBOM’

Benefits of EPR Registration

Effective Waste Management

Get access to a comprehensive framework for Cost-effective waste management.

Recognition

Recycling plays an important role in Swachh Bharat Mission. Recyclers and scrap dealers earn recognition in the larger market.

Environmental Safety

EPR helps in the conservation of natural resources and eradicates pollution. This in turn helps in sustainable development which is important for the consumers and manufacturers

Recycling Plastic Waste

Plastic waste is causing damage to the environment and increasing pollution. It is hazardous not only to human health but also to wildlife. If plastic is not correctly managed, producing new plastic products will be a waste of resources. Hence, plastic recycling is the most essential step toward preventing environmental damage.

Plastic recycling is the process of collecting plastic waste and converting them into reusable products. Almost all products have plastic involved in it. Recycling ensures that plastic is not getting wasted. Instead, it is recycled into plastic granules which are further converted into new products such as benches, chairs, dustbins, etc.

What are the types of plastic that can be recycled?

- PET

PET also known as Polyethylene Terephthalate, is a popular thermoplastic. This material is perfect for producing low-pressure products. Clothing fibers and soft drink bottles are popular products made from PET. - HDPE

HDPE is a Sturdy and opaque, HDPE is used for products like milk jugs, detergent bottles, and some plastic bags. - PVC

PVC also known as Polyvinyl Chloride is a thermoplastic. It is also one of the commonly used plastic materials around the world. PVC is used in wires, pipes, bottles, etc. - LDPE

LPDE is Low-Density Poly Ethylene. It is used to make plastic bags. It is not easy to recycle this material. Instead of recycling, you can clean and reuse them for other purposes. - PP

PP is also a polymer. Manufacturers frequently use it to make plastic boxes, plastic furniture, and plastic jar lids. - PS

PS is a polymer. Examples of products that come from this plastic include plastic cutlery and yogurt containers. - Other

This category includes plastics used in a wide range of products, from bulletproof materials to sunglasses, DVDs, and computer cases.

As shown above, there are different type of plastic and have different recycling process. However, the basic Plastic Recycling Process is as follows:

- Collecting: The plastic waste is collected from various communities by organizing various IEC activities such as door-to-door collection, Beach Cleanups, Collection drives in schools, etc.

- Segregation: Once the plastic waste is collected it is sent to the facility for segregation. Here the waste is segregated according to the type of plastic.

- Shredding: The segregated plastic waste is converted into flakes via shredding.

- Washing: Now the plastic waste is sent to the washing line for cleaning any food particles in it.

- Melting: The plastic waste is heated to the melting point so that it can be further processed into granules.

- Recycled Products: The granules are used for creating and manufacturing eco-friendly recycled plastic products.. this

Our Role in EPR Registration

You can depend on our consistent and timely completion of application forms.

Our team of EPR certificate consultants is committed to guiding you through the documentation and evaluation process.

Our EPR certificate specialists possess the necessary tools and expertise to monitor your application closely.

We will maintain direct communication with

CPCB officials for timely follow-ups and acknowledgements, ensuring all necessary documents and information are readily available when requested by the CPCB.

We diligently work to address any unexpected inquiries or requirements from the CPCB.

In order to exceed your expectations, we devote our energy to fulfilling all requisite formalities.As premier EPR certificate consultants, we offer comprehensive and tailored solutions to all your EPR authorization certificate inquiries.

EPR Authorization for Plastic Waste Management

Plastic has many uses and the improper disposal of plastic waste has become a major threat to the environment. Plastic carry bags and plastic packaging materials are the major contributors to environmental pollution like soil, water, and air, it takes an average of one thousand years to decompose completely. Therefore the plastic waste management regulations in 2011, were introduced, in order to tackle the problem of plastic waste in a scientific manner. In violation of the earlier Plastic Waste Regulations, 2011 the government notified the Plastic Waste Management Regulations, 2016.

The objectives of Extended Producer Responsibility:

The 2016 Plastic Waste Management Rules require manufacturers and importers to properly dispose of or recycle post-consumer plastic waste. Extended Producer Responsibility (E.P.R.) is a business and environmental strategy for managing the lifespan of a product. EPR Authorization is the term used to describe the producer’s responsibility for controlling product disposal after consumers have declared them to be useless. Making it simpler for end-of-life, post-consumer waste to be collected and recycled is a producer’s obligation.

The objective is to develop a system that handles the collecting, sorting, and transportation of waste to a disposal site. These materials can also be utilized in cement kilns, pyrolysis, road construction, and recycling facilities due to their high quality and low cost. End-of-life garbage produced by waste generators, such as brand owners and producers, must be collected. Brands are financially motivated by this to create markets for the reuse, buyback, and recycling of materials. Companies might also assign a third party to complete this duty.

FAQ

The EPR Registration full form is Extended Producer Responsibility

Extended Producer Responsibility refers to the responsibility of management of disposal of those products once labeled as no longer useful by the consumers

Multi-layer Plastic Waste is a type of plastic waste that has multiple layers of plastic, such as packaging chips.

EPR or Extended Producer Responsibility an environment protection strategy for reducing the impact of products and its packaging on the environment. EPR Registration is mandatory in India. It is established by the government ensure that the responsibility of lifecycle of the product including the take-back & recycling the post consumer waste. EPR is a cost effective and most efficient method of recycling.